RECOMMENDED VIDEOS

Steel Stiffener / Steel Lintel

Tuck Hua Metal Works Sdn Bhd

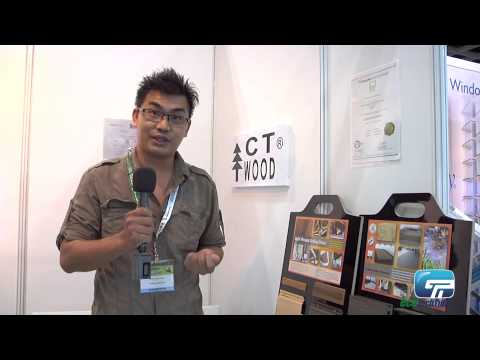

Composite Technology Wood - Combination Rice Husk and PVC…

Composite Technology Wood Sdn Bhd

Heat Shield Solution (Commercial)

Heat Shield Solution

Phoenix Bricks. Eco Friendly

Phoenix Building Products (India) PVT LTD.

Flowcrete - Hygienic Flooring for the Food and Drink Industry

Flowcrete Group Plc

Related Stories

‘House of Trash’ proves how waste can transform into beautiful home design

Whimsical park built of recycled materials pops up in Shanghai

Elevated bamboo peace bridge for the Korean Demilitarized Zone unveiled by Shigeru Ban and Jae-Eun Choi

Colossal cardboard temple pops up in Chiang Mai in just one day

“Cannabis walls” add warmth to this eco-friendly home in Israel

03 May, 2017

UK tests cheaper, longer-lasting roads made with recycled plastic

Green Building Materials, Construction & Design | UNITED KINGDOM | 27 Apr, 2017

Published by : Eco Media Asia

Around 24.8 million miles of roads crisscross the surface of Earth. And hundreds of millions of barrels of oil have been used for that development. Engineer Toby McCartney came up with a solution to that waste of natural resources and the growing plastic pollution problem. His company, Scotland-based MacRebur, lays roads that are as much as 60 percent stronger than regular asphalt roads and last around 10 times longer – and they’re made with recycled plastic.

Our city roads require a lot of maintenance over time as weather deteriorates them and potholes open up. Meanwhile there are around five trillion pieces of plastic in the ocean. McCartney came up with an answer to both issues. He turns 100 percent recycled plastic into what he calls MR6 pellets, or small pellets of waste plastic, which replace bitumen, the material used to bind roads together (extracted from crude oil) and sold by oil companies like Shell.

Normal roads are comprised of around 90 percent rock, sand, and limestone, with 10 percent bitumen. MacRebur’s process replaces most of the bitumen, using household waste plastic, farm waste, and commercial waste. Much of the trash would have otherwise ended up in a landfill.

At asphalt plants the MR6 pellets are mixed with quarried rock and a bit of bitumen, and a plant worker told the BBC the process is actually the same “as mixing the conventional way with additions into a bitumen product.”

McCartney was inspired to design plastic roads after his daughter’s teacher asked the class what lives in the ocean, and his daughter said, “Plastics.” He didn’t want her to grow up in a world where that was true. He’d also spent time in India, where he saw locals would fix holes in the road by putting waste plastic into the holes and then burning it. He started MacRebur with friends Nick Burnett and Gordon Reid.

MacRebur’s first road was McCartney’s own driveway, and now the company’s roads have been laid in the county of Cumbria in the United Kingdom.

Article from inhabitat.com

by Lacy Cooke